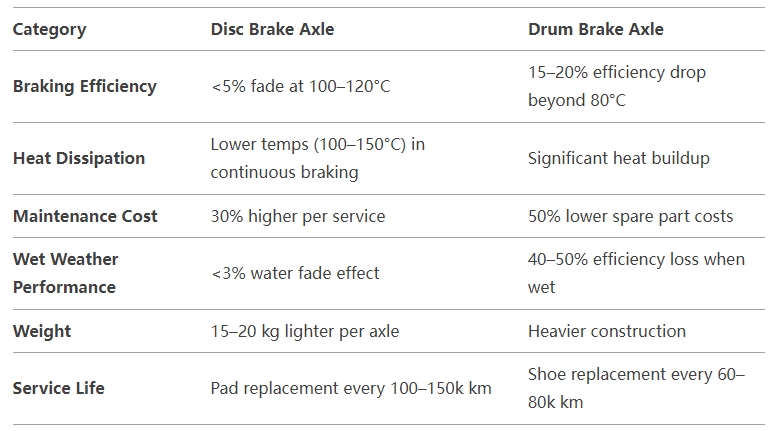

Disc Axle vs. Drum Axle for Trailers

1. Core Principle Differences

Disc Brake Axle:

Uses opposed calipers to clamp the brake disc Open cooling structure Hydraulic/pneumatic piston force transmission Typical response time < 0.3 seconds Drum Brake Axle: Brake shoes expand radially to contact the drum Enclosed design Force transmission via S-cam mechanism Typical response time 0.5–0.8 seconds Technical Note: Disc brakes have 60–80% larger effective cooling area than drum brakes.2. Key Comparison Across 6 Dimensions

3. Real-World Operational Data (6×2 Semi-Trailer Example)

Long Descent (5% grade, 10 km): Disc: 180°C → 95% efficiency retained Drum: 260°C → 72% efficiency remaining Wet Braking Distance (60 km/h → 0): Disc: 36.5 m (vs. 39.2 m dry) Drum: 52.8 m (vs. 41.6 m dry) Total Cost of Ownership (TCO, 800k km): Disc: 18–22% lower maintenance costs Drum: 40% lower initial purchase cost4. Recommended Applications

Choose Disc Brakes For: Mountainous/hilly terrain Hazardous materials/high-value cargo Annual mileage >150k km Cold chain/express logistics Drum Brakes Still Preferred For: Flat terrain at standard loads Construction/mining vehicles Budget-conscious fleets Low annual mileage (<80k km)

5. Industry Trends

Disc Brake Adoption: 90%+ in Europe, 60% in North America, rapidly growing to 35% in China New Materials: Carbon-ceramic discs (50%+ weight reduction) in testing Smart Systems: Knorr SBC2.0 for real-time pad wear monitoring Regulatory Push: EU mandates disc brakes on new trailers from 2025 Final Recommendations: Long-haul logistics: Disc + EBS + TPMS Regional haulage: Drum + auto-adjusters Specialized transport: Liquid-cooled disc brakes Conclusion: Disc brakes are becoming the mainstream choice due to stricter weight regulations and TCO awareness, but drum brakes remain cost-effective for specific applications. Select based on operational needs and fleet management capabilities.

Founded in 2001, DARO Heavy Industry Group has been deeply engaged in the field of commercial vehicle parts for more than 20 years. Through years of continuous research and development and technology accumulation, it has developed mature technologies in trailer Axle, suspension, accessories and other fields, becoming a global R&D manufacturer of commercial vehicle axle/parts with an annual output of more than 170,000 pieces.

DARO Group has 32,000 ㎡ standard chemical plant, laying the industry's leading automated intelligent production line, strictly implementing the ISO9001, IATF16949 quality system standards, starting from raw materials, implementing unified and strict quality control, cooperation customers all over the country and overseas more than 50 countries and regions. It still maintains a record of zero quality disputes.