Products DescriptionUtility trailer axles,no need to disassemble the wheel hub, and the replacement and maintenance of components such as brake pads are more convenient. Higher cost performance, reduced fuel consumption, saved comprehensive vehicle costs. 100% online testing+manual quality inspection, ensuring strict compliance with industry standards and guaranteed qualityModelMax.

Contate agora

Products DescriptionSpoke hub trailer axle:1、The use of unit design, to maintain good sealing under high-speed operation, maintain the internal cleaning of the parts.2、Multi-layer sealing structure, plus sealing sleeve, isolation of pollution, prevent grease overflow.3、With higher stiffness and accuracy, maintain safe operation and extend service life.4、The maintenance process is simplified, the replacement is easier, the user's downtime is reduced, and the operation efficiency is improved.5、The toughness and elasticity of the product are greatly improved, which can effectively buffer and

Contate agora

Products DescriptionDouble axle enclosed trailer axle is the most widely used axle type on semi trailers, and also has the highest proportion in the current market. Compared to other axles, the most obvious advantage of drum type axles is that their prices are relatively low, their accessories are basically common in the industry, and their design is simple, making subsequent maintenance and replacement more convenient.ModelMax.

Contate agora

Products DescriptionDARO 3tons agricultural trailer axle features lighter and more compact shape, higher stiffness and accuracy, high production and processing accuracy, and can maintain good sealing under high-speed operation, maintain internal cleaning of components, maintain operation safety and extend service life. Finished product online testing + manual quality inspection + limit test, the quality is strictly in line with industry standards.ModelMax.

Contate agora

Products DescriptionAmerican type axles are used in the latest models of Single axle dump trailer and trailer accessories1. One-piece shaft tube, high strength, comfortable appearance.2. Compared with other axles of the same load, it is light in weight and low in price.3. Using non-asbestos friction plate, more environmentally friendly.4. Adopting international general specifications, maintenance is convenient, fast and low cost.ModelMax.

Contate agora

Products DescriptionSmall trailer single axle,is a classic light trailer rear axle that adopts a single tire design to reduce its own weight, simplify maintenance procedures, simplify replacement, reduce user downtime, improve operational efficiency, and improve strength and toughness. Safety performance such as rigidity, wear resistance, and fatigue resistance strictly meet the standards.ModelMax.

Contate agora

Products Description8000lbs trailer axle,is a classic light trailer rear axle that adopts a single tire design to reduce its own weight, simplify maintenance procedures, simplify replacement, reduce user downtime, improve operational efficiency, and improve strength and toughness. Safety performance such as rigidity, wear resistance, and fatigue resistance strictly meet the standards.ModelMax.

Contate agora

Products DescriptionDual axle trailer are used in the latest models of trailers and trailer accessories1. One-piece shaft tube, high strength, comfortable appearance.2. Compared with other axles of the same load, it is light in weight and low in price.3. Using non-asbestos friction plate, more environmentally friendly.4. Adopting international general specifications, maintenance is convenient, fast and low cost.ModelMax.

Contate agora

Products DescriptionNorthern tool trailer axle strong and long lasting ——built-in warm rolling forming, strength, toughness, elongation absolutely standard.More handy preservation —— effortless maintenance, keep time, to meet the desires of environment friendly operation.ModelMax.

Contate agora

Products DescriptionSquare trailer axle have high cost performance, relatively low acquisition costs, good heavy-duty performance, large inventory, and more convenient maintenance; The disadvantages are heavy weight and relatively high maintenance frequency. Generally, American type axles can be widely used in various general cargo transportation conditionsModelMax.

Contate agora

Products DescriptionUnderslung trailer axle,It can be matched with different widths/thicknesses/pieces, and the number of leaf springs can be freely selected according to the load. The raw material is made of silicon manganese spring steel, which has a long service life and high load.

Contate agora

Products DescriptionAirbag trailer axle uses airbags instead of traditional leaf spring structures, which are lighter in weight and beneficial for reducing vehicle weight, saving fuel consumption.

Contate agora

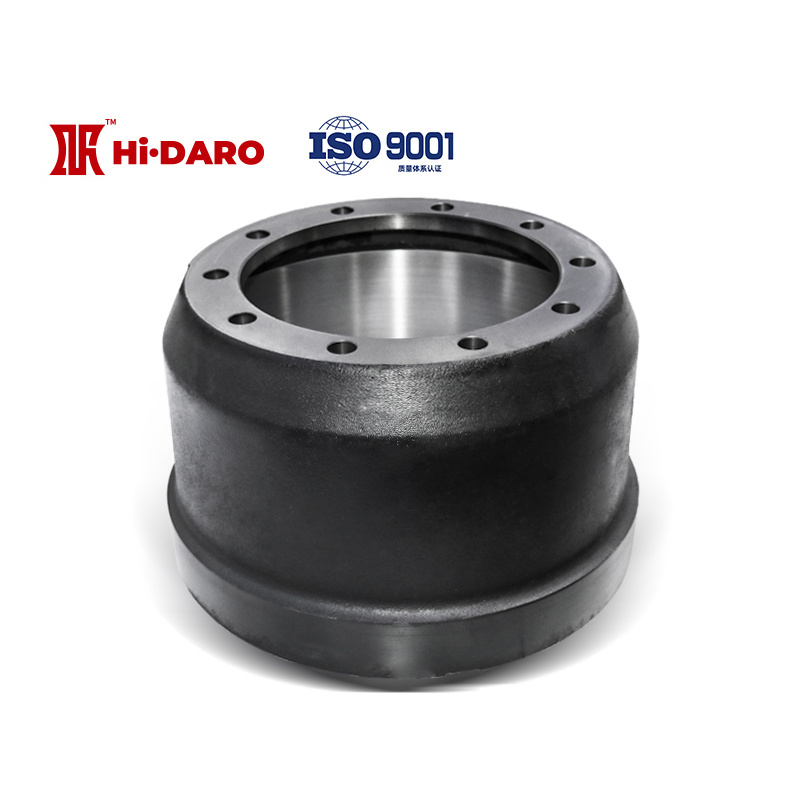

Products DescriptionDARO trailer axle Brake Drum:Select raw materials -——Using lighter weight high-strength alloy raw materials to reduce product weight.Mature process -——heat treatment and tempering, better wear resistance, good fit with brake shoes, improve driving safety.Reliable quality —— faster heat conduction, higher wear resistance, heat resistance, heat dissipation and heat capacity.Authoritative quality inspection -——assembly line production, single inspection out of the warehouse, stable and reliable quality.DARO trailer axle Brake Drum is suitable for 13T-16T drum axle.

Contate agora

Products Description7000 pound trailer axle is a single tire structure with a lighter weight, which can reduce the dead weight of the vehicle, while saving fuel and increasing efficiency, with high cost performance. It can be applied to a variety of trailer chassis. The finished product has undergone online testing, manual quality inspection, and extreme testing, ensuring that the quality strictly meets industry standards.ModelMax.

Contate agora

Products DescriptionUnderslung trailer axle has very powerful functions. In addition to what we often call "lightweight", it can also play a significant role in many aspects such as vehicle height, axle load adjustment, and wheelbase adjustment. The most obvious feature is its airbag type air spring. As an elastic element, the air spring can alleviate the impact load from the road surface when passing through the axle to the vehicle body.

Contate agora

Products DescriptionThe oil seal for trailer axle adopts an optimized pressure bearing design during the production process, greatly improving durability, durability, and stable performance under high-strength usage conditions.

Contate agora

Products DescriptionThe 15000lbs trailer axle electric sold by DARO Group has passed multiple quality inspections such as fatigue test, salt spray test, and magnetic particle inspection test. Matching schemes are available for customers with different needs to choose from.

Contate agora

Products DescriptionUnbraked trailer axle,with welded bracket,adopts an integrated hot rolling process to improve the overall mechanical properties of the axle and has good fatigue resistance and toughness. 100% online testing+manual quality inspection+limit testing to ensure that the quality strictly meets industry standards. Reasonably optimize the production process, resulting in stronger axle consistency and interchangeability.ModelMax.

Contate agora

Products DescriptionSmall trailer axle high rigidity and durability: The axle is made of high-strength steel structure. After precision welding and strict quality control, it has high rigidity and durability, which can ensure that it is not easily deformed or damaged during long-term use, significantly improving the durability and durability of the vehicle. safety.ModelMax.

Contate agora

Products DescriptionThe difference between American type trailer axle tube produced by DARO Group and German axle tube mainly lies in the axle head. The axle head and shaft body of American type trailer axle tube are shaped from a 20Mn2 seamless steel pipe. There is no need for manual welding in the middle, so the connection is more natural and load-bearing. In addition, the axle head has higher bit wall thickness and is more durable and resistant. Therefore, compared with German axle tube, American type trailer axle tube has better load-bearing capacity.ModelMax.

Contate agora

Products DescriptionMulti-layer sealing structure, plus sealing sleeve, Double axle trailer isolation pollution, prevent grease overflow.Higher stiffness and accuracy, maintain safe operation, prolong service life.ModelMax.

Contate agora

Products DescriptionDARO trailer axle replacement adopts a new American axle design, which is integrated heat treatment and forming, eliminating manual welding. The axle head and axle body are built from a steel pipe, which has stronger load-bearing capacity. Fifteen national standard process Settings, online and offline double quality inspection, production accuracy strict standards; Product design fully in line with industry standards, universal accessories, easy maintenance; No bending and deformation under high strength, ensuring long-term and efficient operation of vehicles.ModelMax.

Contate agora

Products DescriptionDouble axle tilt trailer axle Using 20Mn2 excessive electricity alloy seamless metal pipe, product fantastic is greater reliable.Strong bearing capacity, to make sure the long-term environment friendly operation of vehicles.With more desirable bending and torsional resistance, no bending and deformation below excessive strength.ModelMax.

Contate agora

Products DescriptionLight duty trailer axle Partially reinforced square axial beam with large section coefficient and strong torsion and bending resistance.The overall heat treatment technology improves the overall mechanical performance of the axle and has good fatigue resistance and toughness.Braking is sensitive and more stable, and it is safer to cooperate with ABS and EBS systems in braking.ModelOffset(mm)Axle loadBrake(mm)Wheels InstalledTireDRP091209377*4510/280/335/M22*1.519.5"/20/22.5DRP0909377*458/220/275/M22*1.519.5"DRP099377*458/220/275/M22*1.519.5"DRP1111377*458/220

Contate agora